Manufacturing Capability

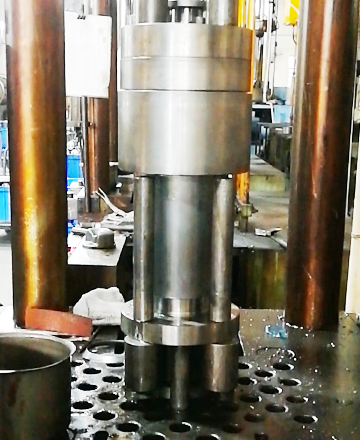

Pressing & Deep Drawing

Deep Drawing process can make part from sheet metal to thin-walled with cylindrical, stepped, tapered, spherical, box-shaped and other irregularly shaped. It can also arrange in pairs with others stamping processes to produce complex parts. With our 600T hydraulic press, a max. Dia700mm hemisphere can be produced.

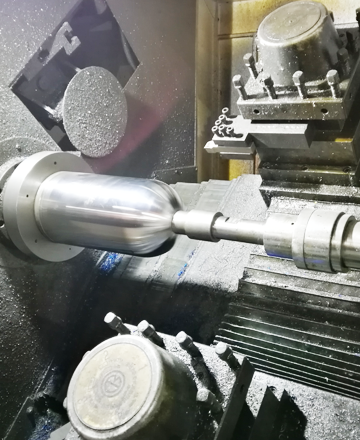

CNC Metal Spinning

Metal spinning is a kind of spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Our CNC spinning machines are equipped with models 600SR, 800DR & 1450SR which allows making reel plate with Dia900mm.

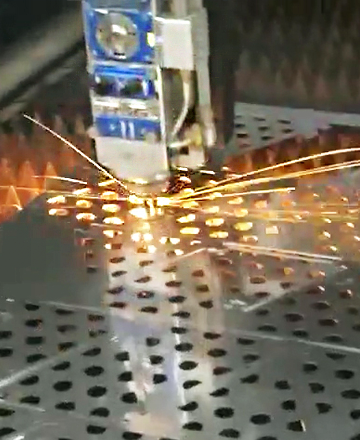

Laser Cutting & Welding

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, leaving an edge with a high-quality surface finish. Our laser cutting machine is 1500W that can cut steel plate up to thickness 5mm.