How can we move your product from prototype to production?

TAKSANG is ready helping with design for manufacture (DFM),with our n-house engineering and sales team with experience in determining whether your conceptual idea will translate into a consolable production opportunity.

SOURCING & RFQ

You provide a drawing or a prototype to us, and then we will provide a detailed quote and project proposal to move into mass production.

Sometimes, specific components used in the prototype will be swapped out based on availability. The result is a quote and project approach that are most effective and efficient for you.

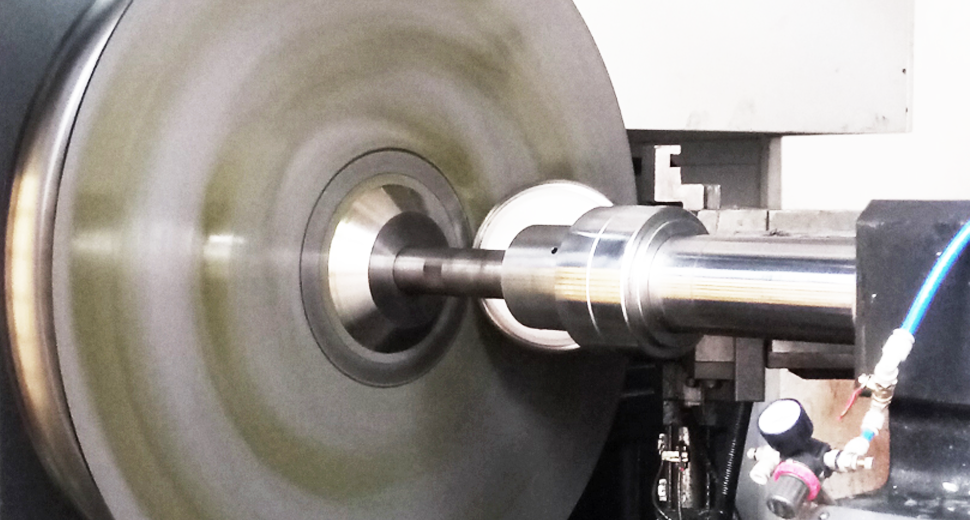

TOOLING & SAMPLING

Once the quote is approved, the product enters the tooling/sampling phase, which is also known as non-production release (NPR). During this phase tooling is completed and the design is turned into a physical sample that can be consistently replicated while meeting product specifications. This process is truly iterative. Initial samples often need tweaking. There might be additional design changes, meaning additional samples and additional time.

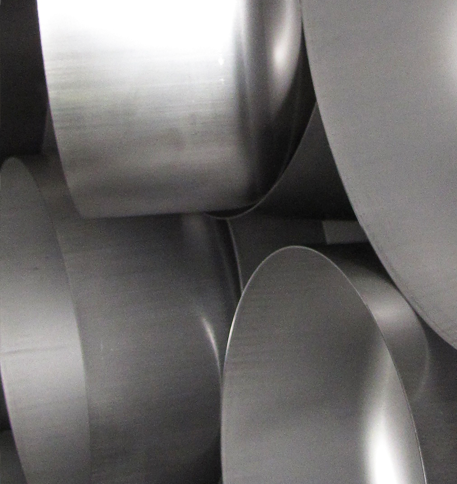

PRODUCTION LAUNCH

After a pilot production run — a short-term run of a small batch, usually 200 to 500 pieces, depending on complexity, size and volume of the product — your sample has been qualified and your product is ready for mass production. Quality control observes and inspects factory production, reporting any significant quality issues that arise. During production review, several critical analyses can occur, including Process flow analysis, Handling of unexpected conditions & Inspection of finished goods and packaging. When production is complete, the final product is inspected against both the quality procedure and previously approved samples.