Metal Spinning / May 30 , 2021

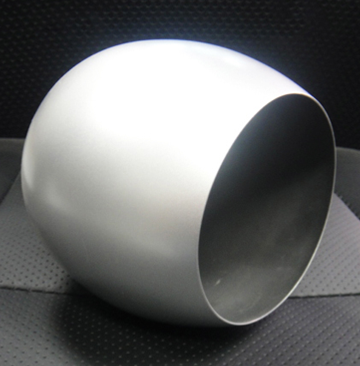

Stainless Steel Venturi Tube made by CNC Spinning for automotive industry.

- Market: China

- Industry: Automotive

TAKSANG has a design team with skilled experienced engineers offering a dedicated service to our customers, providing a cost-effective solution to potential new products.

TAKSANG work with our customers to provide alternative manufacturing techniques to improve build quality and time savings to ultimately give a cost reduction in mass production.

Quality inspection is done during the manufacturing process to ensure product quality as the approved sample, and a final quality inspection will be carried out before the shipment.

After client received the metal parts, we would follow-up the parts and customer feedbacks & improvement advice in order to build long-term business relationship with every buyer.

We specialize in making sheet metal parts by stamping, punching, pressing, deep drawing & CNC spinning, and also being professional in mold & tooling. Besides, we export stainless steel items such as barware, tableware, household & other OEM promotional items.

read more

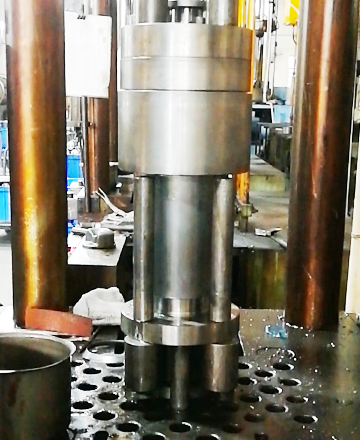

Deep Drawing process can make part from sheet metal to thin-walled with cylindrical, stepped, tapered, spherical, box-shaped and other irregularly shaped. It can also arrange in pairs with others stamping processes to produce complex parts. With our 600T hydraulic press, a max. Dia700mm hemisphere can be produced.

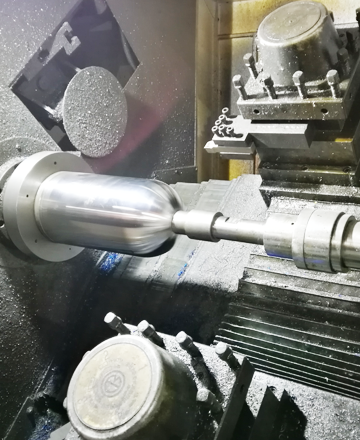

Metal spinning is a kind of spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part. Our CNC spinning machines are equipped with models 600SR, 800DR & 1450SR which allows making reel plate with Dia900mm.

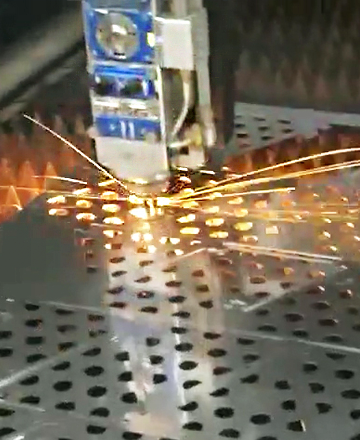

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, leaving an edge with a high-quality surface finish. Our laser cutting machine is 1500W that can cut steel plate up to thickness 5mm.

We work with a variety of material in our metal manufacturing processes. Every metal behaves differently in the stamping / pressing / drawing / spinning process, but our experience and expertise enables us to produce all types of metal parts with the same high levels of quality and precision. We can manufacture certain metal parts from Steel, Stainless Steel, Aluminium, Copper & Titanium.

We manufacture all of our own tooling, dies, and fixtures. Our state-of-the-art tooling department enables us create high precision tooling and dies for even the most complex metal stamping and fabricating projects.

1. Tell us your ideas 2. Send us your drawings (2D/3D) with material grade & dimensions, if any 3. Advise your order quantity & other requirement 4. Email all to hello@taksang.com.hk 5. We shall get back to you asap

Recent Completed

Project

Hong Kong

Hong Kong

China

China

Metal Spinning / May 30 , 2021

Deep-Drawing / March 30 , 2021

Stamping / Aug 30 , 2020